Tuyere Design for Blast Furnace

Engineering Challenges

- Combustion characteristics of coal across different tuyere & lance configurations

Ansys Solutions

- Porous media capability

- Reaction & species transport modeling

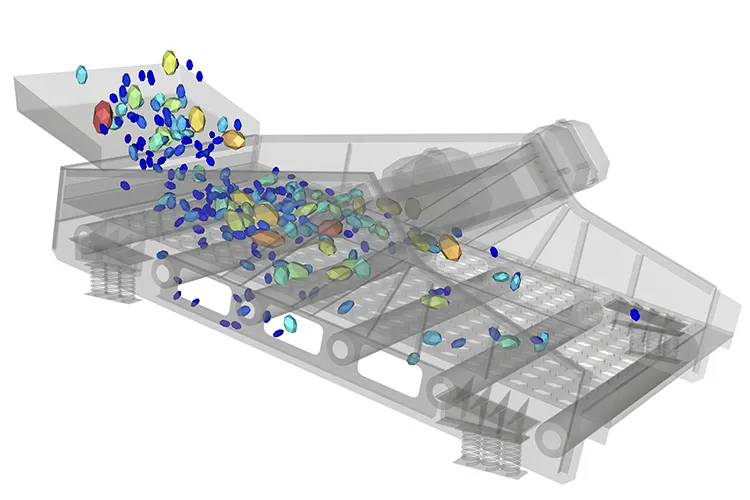

- Discrete Element Method (DEM)

In the steel industry, processes operate under extreme temperatures and demanding conditions where precision, safety, and efficiency are critical. Ansys simulation solutions enable engineers to model and analyse every stage of steel production — from casting and rolling to forming and thermal management. By predicting material behaviour, optimizing equipment design, and improving process efficiency, Ansys helps manufacturers reduce downtime, minimize energy consumption, and ensure safer, more cost-effective production.

Key engineering challenges across stages and the corresponding Ansys capabilities to solve them.

Our HFSS Solution provides a comprehensive suite of electromagnetic simulation capabilities designed to support research, design, and development across various industries. This includes expertise in antenna design, RF and microwave components, signal integrity analysis, and electromagnetic compatibility, leveraging advanced simulation technologies to accelerate innovation, optimize performance, and ensure reliable, high-quality products.

Adding {{itemName}} to cart

Added {{itemName}} to cart